PID

PID

PID is Proportional – Integral – Derivative control. It is the very commonly used in process control, heating control and motion control. The PID function calculates the “error’ value between a measured process variable and the desired setpoint. It adjusts an output in an attempt to minimize the error. This adjustment occurs on a regular period. Each time an adjustment is made, it takes into account the magnitude of the error (Proportional), the accumulated total of the error over time (Integral), and the rate of change of the error (Derivative).

If you are new to PID there is a good description of PID on Wikipedia.

In vBuilder, PID control is a background task. That means that you Start it and it will continue to run in the background, constantly calculating the error, integrating it and determining its rate of change and updating the output based on these factors combined with the constants that you set up. Once started, the PID will operate until it is Paused

The basic PID equation used in the PID function of vBuilder is :

O = P*E + I * ∫ E dt + D * ΔE/dt

where : O : Output

P : Proportional constant (sometimes referred to as the Gain)

I : Integral constant (sometimes referred to as Reset)

D : Derivative constant (sometimes referred to as Rate)

E : Error

dt : change in time

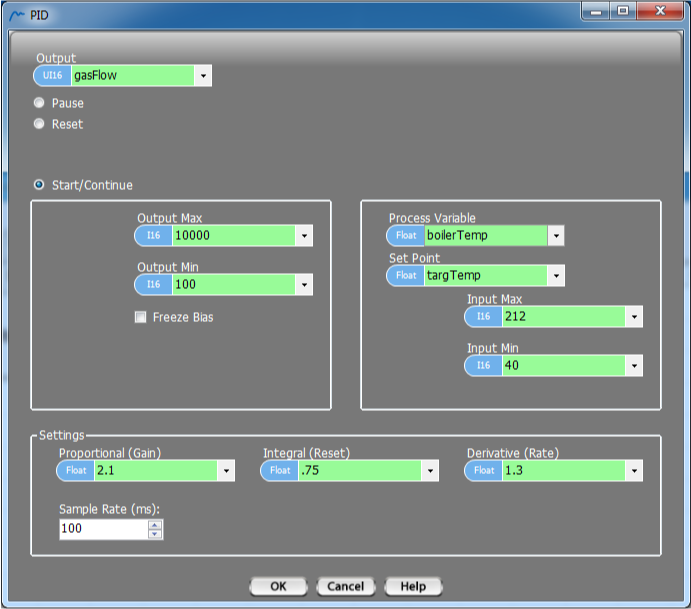

Start/Continue

PID only has to be started once. It will continue to operate until it is Paused.

Start/Continue uses the following parameters:

• Output: This is what the PID is actually adjusting. The Output should have a direct impact on the value of the Process Variable. For example, a butterfly valve controlling the gas supply to a boiler’s burners has a direct impact on the temperature of the boiler.

• Output Max: The maximum value allowable for the Output. Regardless of the result of the PID calculation, the Output will be restricted to no more than this value. [any variable type except Bit and ui8]

• Output Min: The minimum value allowable for the Output. Regardless of the result of the PID calculation, the Output will be restriced to no less than this value. [any variable type except Bit and ui8]

• Process Variable: This is the measurement of the parameter that you are trying to control.

• Set Point: This is the desired value of the Process Variable at this time

• Input Max: The maximum value of the Process Variable measurement that will be used for the PID calculation. If the actual measurement goes above this value, this value will be used.

• Input Min: The minimum value of the Process Variable measurement that will be used for the PID calculation. If the actual measurement goes below this value, this value will be used.

• Proportional: The constant multiplier to the error.

• Integral: The constant multiplier to the integral of the error.

• Derivative: The constant multiplier to the derivative of the error.

• Sample rate: The amount of time between each PID calculation/adjustment, in milliseconds.

• Freeze bias: This is a selectable option. If selected, it is used to limit the impact of integral portion of the equation to no more than the entire Output range. This is useful in preventing overreaction after a time period where some factor prevented the actual control of the Process Variable [which could possibly result in a huge integral value].

When you Start a PID, it will continue operating at the defined sample rate, behind the scene. In other words, once you start it, you don’t need to continue to execute PID Start/Continue blocks for operation. It doesn’t hurt anything if you do. Its just not necessary.

Pause

A PID Pause block stops the PID from operating.

Select the Output variable of the PID that you want to pause, as shown on the right.

Reset

Reset

A PID Reset sets the Integral value to the value required to produce an Output equal to the Reset Value. You should do when starting a PID. The Start/Continue does not initialize the Integral value, because it does not know whether this is the actual Start or whether it is a Continue. When you place a PID Reset in a flow chart, select the Output variable of the PID that you want to reset, as shown on the right. Select the value of the PID output to start the PID with.