Motion Out

Motion Out

Motion Out is used to control a Stepper Output. It’s a background task that once executed, will continue to send signals to motor until it’s reached it’s programmed destination. While Motion Out will create the logical signals for your motor, you’ll need a driver to interface between your PLC and the motor.

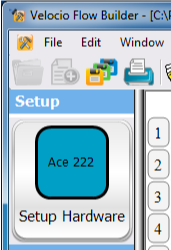

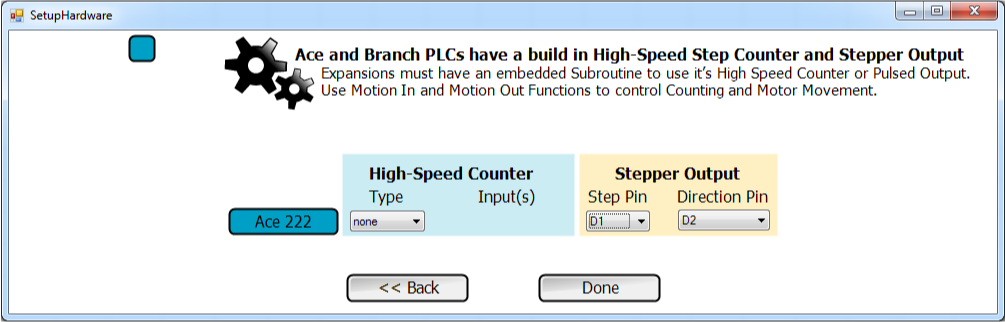

To enable Motion Out, Press the ‘Setup Hardware’ button. It’s on the upper left of vBuilder. Your ‘Setup Hardware’ button may look a little different from the one on the left, depending on whether you’ve setup your hardware and on the specific hardware you’re using.

The last page of the Setup Hardware lets you set Motion Out (Stepper Output) options.

Shown below is what the setup page look like. Click to enlarge.

Above shows 1 device setup for Motion Out. With Branch you can set up a Motion Out for you Branch PLC and for every Expansion that has an Embedded Subroutine.

You’ll need to specify 2 Digital Output Pins. One to control the Step signal and the other for the Direction Signal. Make sure you don’t select the same pin for both signals.

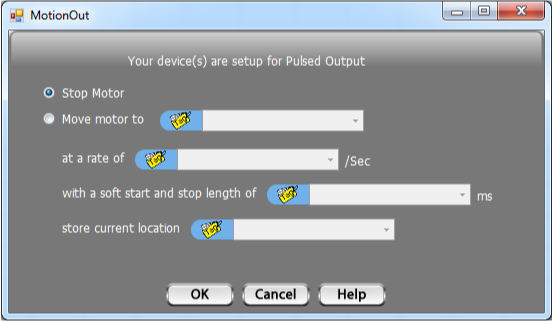

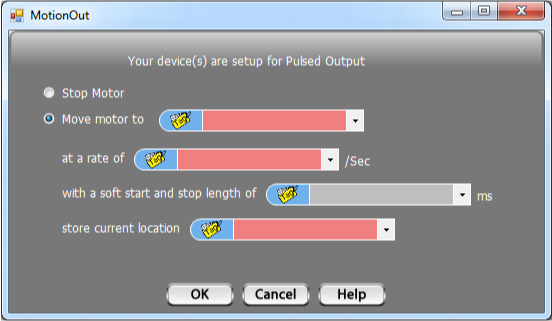

Placing a Motion Out block is simple. Below is the Motion Out Dialog box.

Motion Out needs to know:

Motion Out needs to know:

- Your desired destination. Motion Out will move the Motor from where ever it starts to this destination. Maybe your motor’s current location is 200 and you’d like to move to a destination of 300. This would require the Motion out to Move the Motor 100 steps. Use a number or I32 Tag for this.

- Speed to travel (pulses per second). Use a number or Tag(I16, UI16 or I32) for this.

- What I32 Tag you want to store the motor’s current location in.

- Soft start length (optional, but typically a good idea). Motors often need to be brought up to speed over a period of time. This enables that. Just tell it how long you’d like it to take (in milliseconds) to go from stand still to speed. This will be applied to both ramp up and ramp down.

<– Stop Motor immediately stops signals to move your motor. This isn’t generally good for motors, thus is used primarily in emergency stop situations.